New light links bend and stretch to future devices

Researchers worldwide are working on materials to better integrate humans with their technology, and a new development in the field of optics may provide a way to link it all together.

Various electronics that bend and fold have been demonstrated in recent years, suggesting it may one day be possible to make more wearable devices, even melding them into our clothes, but these systems would remain isolated without a good way to communicate.

Stretchable fibre optical cables for light-speed communication have been developed by Belgian engineers.

The optics would lengthen when someone wearing body sensors bends to tie their shoe, or contort when a robotic arm twists through a full range of motion.

Researchers at Ghent University and imec - a micro- and nano-electronics research centre - in Belgium, say they have produced the first optical circuit that uses interconnections which can twist and conform to changing situations.

These new interconnections are made of a rubbery transparent material called PDMS (poly-dimethylsiloxane). They can guide light along their path even when stretched up to 30%, or when bent around an object the diameter of a human finger.

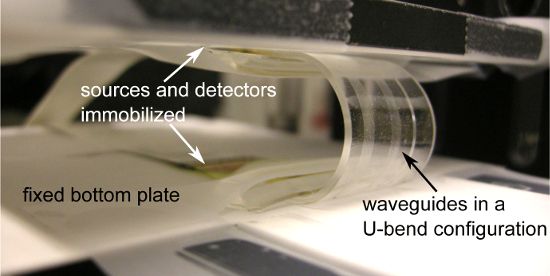

Furthermore, by integrating stretchy interconnections into a circuit – with a light source on one end and a detector on the other – the researchers created a miniature stretchable, bendable “link” that could be incorporated into optical communications systems.

A major breakthrough is the ability to carry light in the same way while cables are stretched as when they are static.

Previous attempts had tried embedding waveguides in the material, but researchers say this did not yield the needed result when stretched.

In the new method, the stretchable substance itself is the waveguide.

This is achieved by a layered approach - a transparent core through which the light travels is surrounded by another transparent layer of PDMS with a lower refractive index. This configuration traps light in the guide’s core, allowing it to propagate along its length.

“We were surprised that stretching had so little influence on the waveguides and also that their mechanical performance was so good,” Ghent University researcher Jeroen Missinne said.

The guide’s reliability was deemed “remarkable”.

The researchers reported no degradation in the material after mechanically stretching it to a 10 percent elongation 80,000 times.

But, Missinne says; “waveguides are useless if you cannot launch light into them and collect light on the other end. If you want to obtain a truly stretchable optical link, the light sources and detectors need to be integrated together with the stretchable waveguide.”

In this instance, a VCSEL (vertical-cavity surface-emitting laser) provided the light, and a photodiode was the detector.

More details are available in the report published by the journal Optics Express.

Print

Print