New polymer folds plastic for future use

A lively new polymer is being developed that can change its shaped based on internal programming.

A lively new polymer is being developed that can change its shaped based on internal programming.

The animated plastic could have broad applications wherever shapes need to change, but researchers say implants, optics and other biological scaffolds are the most obvious use.

The new set of materials start as flat slabs, but when a small temperature variation is applied they can morph into shapes controlled by patterns written into their layers.

The active material needs a few layers for its magic. First, a layer of liquid crystal elastomer (LCE) is combined with a rubbery grid of cross-linked polymers lined up along a single axis, called the “nematic director.”

This is combined with a thin layer of everyday polystyrene, either above or below the LCE.

Without the polystyrene in place and a changing temperature, the LCE tries to contract or expand, but the stiffer polystyrene layer prevents this and instead causes wrinkling, bending or folding of the entire material.

A breakthrough came at the Rice University lab i the US, when researchers discovered the layers would react to heat in a predictable and repeatable way.

This has allowed configurations to be designed into the material depending on a range of parameters; the shape and aspect ratio of the LCE, the thickness and patterning of the polystyrene and even the temperature at which the polystyrene was applied.

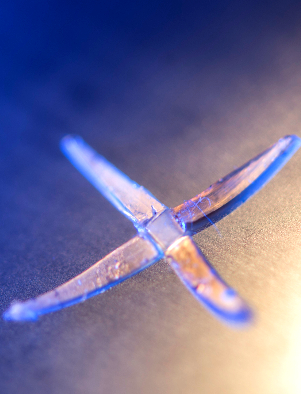

In models so far the polymers has been made into spiralling, curling and X-shaped materials that can close themselves up or even stand on four legs.

Like some sort of self-assembling origami, engineers say the material can be used for just about any design, as long as the pattern layout is correct.

“We already know the materials are biocompatible, stable and inert,” said Rice polymer scientist Rafael Verduzco, “so they have great potential for biological applications.”

“For any application, you would want to be able to change shape and then go back,” Verduzco said.

“LCEs are reversible, unlike shape-memory polymers that change shape only once and cannot go back to their initial shape.

“This is important for biomedical applications, such as dynamic substrates for cell cultures or implantable materials that contract and expand in response to stimulus. This is what we are targeting with these applications.”

The research is the subject of a new paper in the Royal Society of Chemistry journal Soft Matter.

The following video shows the material having a bit of stretch in its testing phase.

Print

Print