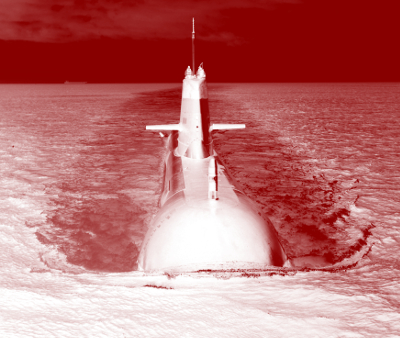

New team for high-tech subs

A new partnership aims to install specialised 3D-printers on submarines.

A new partnership aims to install specialised 3D-printers on submarines.

Australia’s submarine sustainment organisation, ASC, is collaborating with Australia’s national science agency, CSIRO, and DMTC Limited, to pioneer the use of additive manufacturing for the repair of Collins Class submarines.

They are working to develop 'cold spray' technology for repairing damaged metal surfaces, to enable the future in situ repair of submarine components.

The idea is for a submarine to be able to fix itself while out on operations, so that it can remain at sea for longer, without the need to dock for lengthy repairs.

Cold spray is an additive manufacturing and repair method that uses a stream of supersonic gas to accelerate metal powder particles at a surface, building up a dense deposit.

The innovative process occurs below the melting temperatures of the metals involved, which avoids damaging the structural integrity of the components and surrounding area.

“CSIRO and ASC have been working together for a number of years, exploring ways to use cold spray of nickel to repair corrosion,” says CSIRO research team leader Dr Peter King.

“CSIRO has spearheaded the adoption of cold spray by Australian industry since first introducing the technology 18 years ago.

“We have developed unique cold spray-based solutions for the printing industry, aerospace, rail and for combating marine biofouling. The team is focussed on working closely with local companies to develop new intellectual property for Australia and to deliver on national missions such as building sovereign capability,” Dr King said.

The project will see ASC engineers working with CSIRO's Lab22 research facility for additive manufacturing of metals, in Melbourne, to develop portable equipment for in-situ repair in the confines of a submarine.

Once successfully proven and certified, ASC will be licensed to use cold spray to support its work as Australia’s submarine sustainment organisation, primarily in supporting the Collins Class submarine fleet.

A cold spray demonstration video can be seen below.

Print

Print