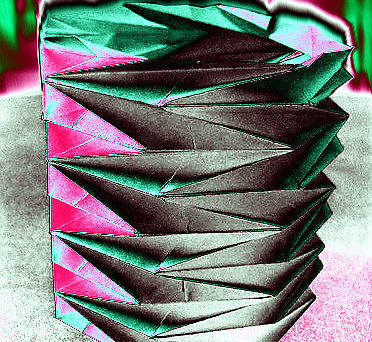

Folding sheets for new prints

Japanese scientists have unveiled a groundbreaking ‘4D printing’ method.

Japanese scientists have unveiled a groundbreaking ‘4D printing’ method.

A fusion of 2D printing, origami, and chemistry, the new technique promises rapid fabrication of complex objects without any waste material.

Its designers say it allows shapes to self-fold in a matter of seconds, bypassing typical time-consuming and resource-wasting 3D printing processes.

Known as ‘4D printing’, the concept aims to overcome the limitations of traditional 3D fabrication methods. By utilising materials with special properties, capable of self-folding into intricate 3D shapes under specific conditions, the method reduces material usage and enhances efficiency.

It is called ‘4D printing’ because the process of self-folding “necessarily makes use of time, which is often said to be the 4th dimension”, the scientists say.

Leading the development of the breakthrough is Project Assistant Professor Koya Narumi from the University of Tokyo's Department of Electrical Engineering and Information Systems.

Explaining the process, Narumi says; “We’re creating flat sheets with origami patterns on them, and these patterns can be complex, taking even a skilled origami artist hours to form. But thanks to our special process, you can pour hot water over these flat sheets and watch as they spring into complex 3D shapes in a matter of seconds”.

The technique involves a specialised UV-reactive inkjet printer, which imprints a 2D origami design on both sides of a heat-shrinking plastic sheet.

The ink resists shrinking, while the base sheet contracts under heat. By strategically leaving gaps between sections of ink, designers can control the folding direction.

Applying hot water to the flat sheet triggers the spontaneous origami-like transformation.

The team spent over a year refining hardware and materials, achieving an astonishing 1,200 times improvement in output resolution compared to previous attempts.

This leap in quality makes the designs not only eye-catching novelties but also viable for real-world applications. Narumi envisions exploring functional materials like conductive or magnetic inks for future possibilities.

The potential applications of this technology seem boundless. In the fashion industry, notorious for material wastage, bespoke designs could be efficiently realised.

Additionally, the ability to transport pre-folded shapes as flat objects opens doors for logistics and storage solutions. Consumers could receive printed designs in the mail, which could be easily transformed into the desired product with the application of heat.

Its designers say disaster recovery efforts could also benefit from this innovation, with medical items and other essentials efficiently transported in flat form, reducing logistical challenges.

More details are accessible here. A video demonstration can be seen below.

Print

Print